Why ISEC

We deliver on our promises. We are talent stacked with over 1,300 solutions specialists, a 25+ offices national footprint, and an employee owner business model. We provide the culture, financial stability, and commitment to ensure the success of every project.

By the Numbers

Relationships Matter.

Every ISEC team member is driven by a spirit of excellence, which is carried out through our core values:

- Commitment to Customer

- Integrity

- Respect

- Safety

- Teamwork

Our teams bring industry leading talent, skill, passion, alignment, and collaboration to every project and relationship. They are the reason for our success, day-in and day-out. We help them develop their craft through:

- Clear and measured performance standards

- Employee recognition programs

- Learning and development programs for all levels of leadership

Experience Matters.

Being in business for over a half century brings a lot of experience to the table. Our Subject Matter Experts are the best in the business. Their success has been achieved through years of technical and practical training, reinforced by specialized market knowledge. Many of our team members have been recognized nationally for delivering results in some of the most demanding, difficult, and high-profile projects in the industry.

The make-up of the ISEC team includes:

- 7.8 -year average tenure

- Self-perform labor model

- 700+ field craft professionals

- Zero punch list program adherence

Financial Strength Matters.

ISEC is a company built on employee ownership. As such, personal and company financial performance drives engagement from every level and every contributor, across the project delivery continuum. In short, we win when you win.

The strength of our company is highlighted by:

- Lowest workers’ comp rates in the industry

- Project bonding to $1B +

- $8B + in construction contracts completed

- $170M+ in assets

Solutions Matter.

We are focused on bringing the right solutions to each objective, regardless of project delivery method. To do so, we align our expert teams with the industry’s best manufacturing partners, all of whom are committed to quality and on time delivery. This approach allows us to:

- Create and drive a global manufacturing network, with unlimited capacity

- Execute Integrated Project Delivery (IPD), sustainable, and prefabrication-focused delivery methods

- Serve as a total solutions provider from concept to closeout

ISEC in Action.

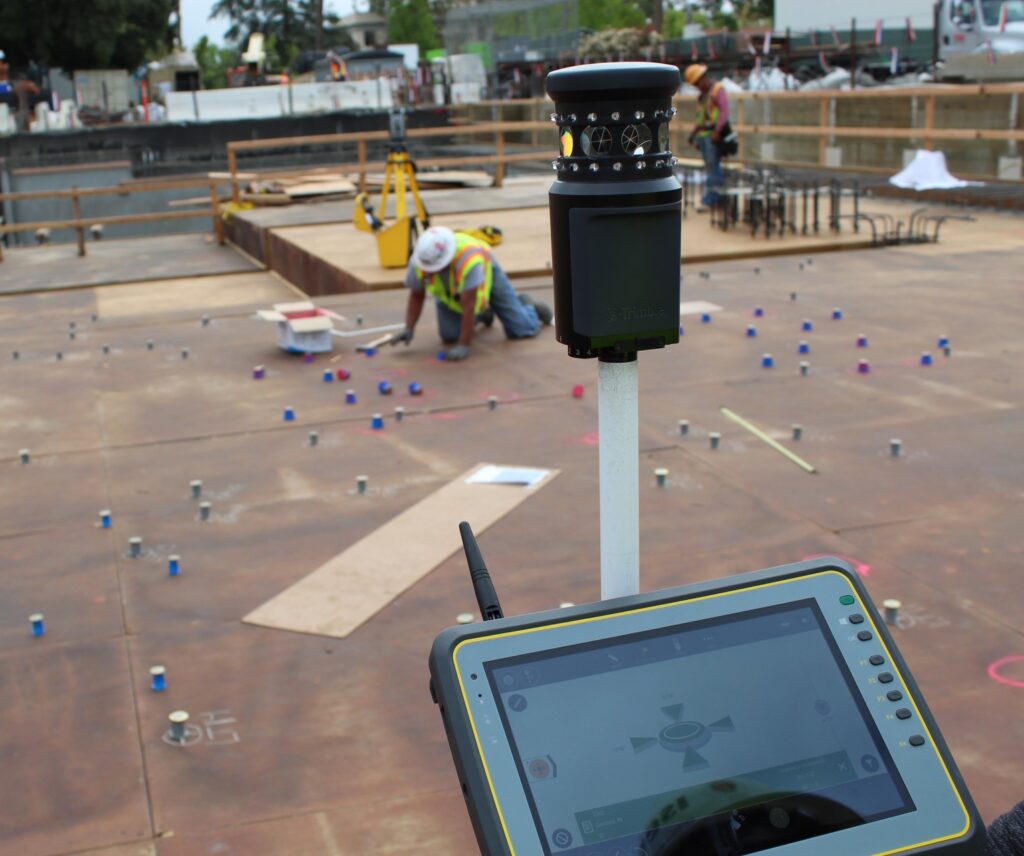

Sutter Health California Pacific Medical Center

What is most notable on VNGC was our role as a selected Risk and Reward Trade Partner. This large, award-winning, hospital project in the heart of San Francisco was delivered using the Integrated Project Delivery (IPD) method. The collaborative efforts of our ISEC team, along with all other stakeholders, helped eliminate any potential issues that were resolved in real time.

ISEC participated in the design and construction of our scopes of work and was a vital part of the effort to drive Lean process to reduce cost, improve productivity, and support the theme of constant improvement at all levels.

There was a culture of constant improvement, transparency, and trust. We succeeded in our mission to build a world class project.

Location

Client/Owner

General Contractor

Architect

ACE AWARDS

ISEC positively handled many major challenges including material handling and operations, international product supply chain constraints, and the COVID-19 pandemic while working on the McGregor Square project. The team of 30 talented ISEC-employed installers quickly adapted to unpredictable material transportation options, impacting the vertical mobility of supplies.

A skip elevator was used at the beginning of the project to tackle the material transportation to the 12 different floors. As the project progressed, passenger elevators soon became the main vertical transportation method, completely changing how our team loaded the materials for transport and impeding the amount of material that could be transported at any given time. ISEC also built temporary pre-fabrication hardware rooms in each of the three buildings for on-site storage, assembly, and material management, allowing for minimal disruption to other trades while employing lean construction principles.

Finally, ISEC managed many national and international vendor supply chain limitations due to the COVID-19 pandemic, quickly ordering material for release prior to international lockdowns and ensuring the project stayed on schedule. Thinking outside of the box, ISEC also sourced local vendors for any quick turn owner changes.

Location

Client/Owner

General Contractor

Architect

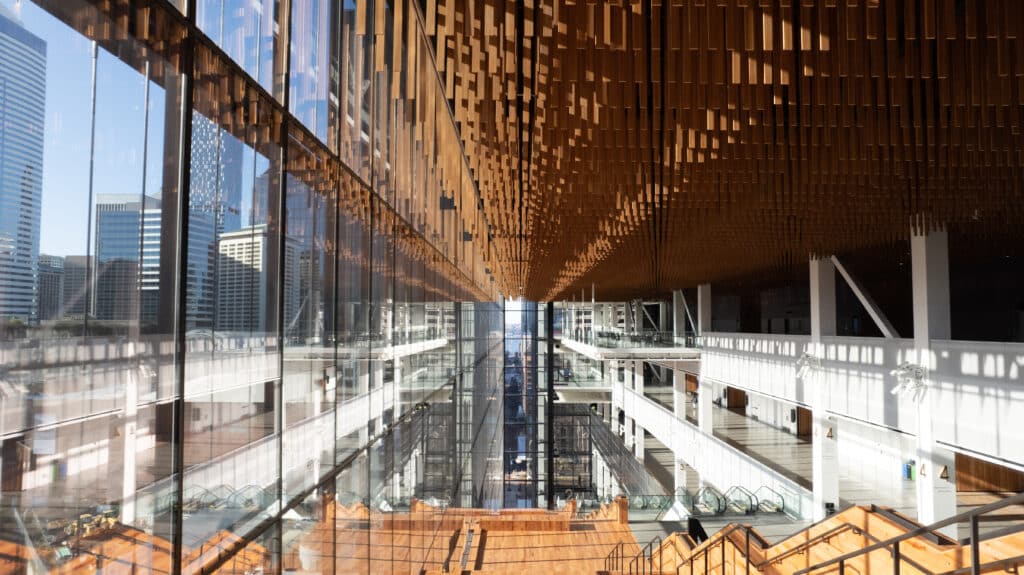

Seattle Convention Center

The Challenge

ISEC faced a complex project involving several unique wood ceiling systems, none of which had been built before. At the bid stage, critical details and specifications were incomplete, and some of the selected materials did not meet the design intent. The sealed bid format restricted clarifications or exclusions, putting the project’s timeline, budget, and quality at risk. We couldn’t accurately define material lead times, costs, or performance parameters, adding to the uncertainty.

The Solution

After being awarded the subcontract, ISEC joined design sessions with the general contractor, architect, and owner’s representative, collaborating closely to address the project’s challenges. We engaged our network of custom millwork manufacturers to review and develop solutions that met both aesthetic and performance requirements. For the wood comb ceilings, we selected Laminated Veneer Lumber (LVL) to ensure dimensional stability, avoiding the warping and twisting that could occur with the initially specified materials. By sawing and re-configuring the LVL, we created architectural-grade wood panels which combined stability with a refined appearance.

The Results

ISEC successfully delivered custom wood ceiling features, including wood combs, chandeliers, wormwood planks, and meeting planks, all of which turned out warm, natural, and visually stunning.

Lessons Learned

This project highlighted the importance of early design influence, engaging vendors for creative solutions, and building offsite mockups for unique features, ensuring that ISEC could deliver exceptional results despite initial challenges.